Turbine Health Assessment: Impact Testing

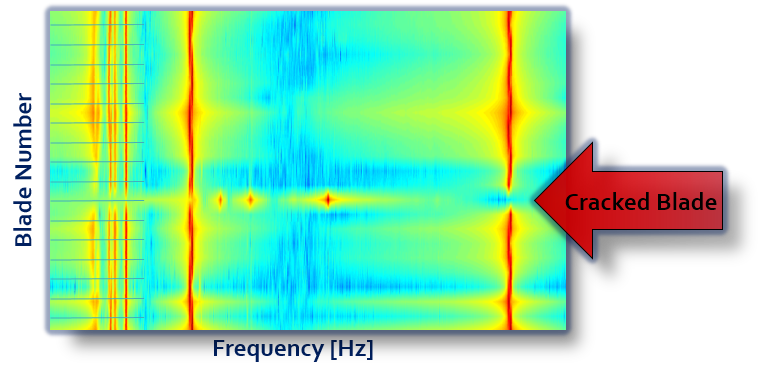

Rapid turbine blade impact testing to identify cracked blades using natural frequency shifts.

A simple hammer impact will excite the natural frequencies of the turbine blade. The blade will ring with its unique frequencies those are closely related to its physical conditions. Cracks/Flaws will shift the blade natural frequencies. It is a simple and fast way to identify cracked turbine blades. Similar testing could identify blade group frequencies (axial, tangential and twisting) to avoid resonance conditions of new and retrofitted turbines.

Applications

- Rapid Health Assessment

- 120Hz Exclusion Zone of Blade Groups

- Quality Assurance

- Specification Verification

- Blade Natural Frequency Scattering

- Turbine Repair Check

Industries

- Electric Power Generation

- Aviation and Aerospace

- LNG Compressors

Measured Modal Parameters

- Natural Frequencies

- Relative Damping Ratios

- Mode Shapes

Turbine Blade Experimental Modal Testing: Modes Shapes

1st Mode

2nd Mode

3rd Mode

4th Mode

Blade Group Vibration: Mode Shapes (Blue Dots: Individual Blades, Red Dots: Turbine Wheel)

305Hz

Axial Mode

428Hz

Axial Mode

605Hz

Tangential Mode

758Hz

Tangential Mode

1176Hz

Twisting Mode

1246Hz

Twisting Mode