Torque and Power Measurement System

The Torque and Power Measurement System (TPMS) was developed to address the industry’s need to have accurate, real-time torque and mechanical power measurement of shafts and rotor systems.

Features

- Instantaneous Mechanical Power Measurement

- Static and Dynamic Torque Measurement

- Static and Dynamic Power Measurement

- Up to 1000 Readings per Second (1KHz)

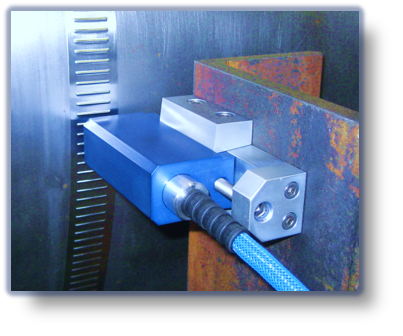

- Contactless: Maintenance Free Operation

- One Hour Encoder Belt Installation with Micro Spot Welding

- Encoder Belt can be Installed Using Epoxy Adhesive

- Lightweight Encoder Belt: 12 gram/m

- Analog Voltage/Current/Modbus Outputs

- For Testing and/or for Permanent Installation

- Not affected by Dust/Dirt/Oil/Water/Grease…

- Immune to Electrical Noise

- Easy Gap Adjustment During Operation

- Hazardous Location (Explosion-Proof)

- Temperature Range: -73°C to 230°C, (-100°F to 450°F)

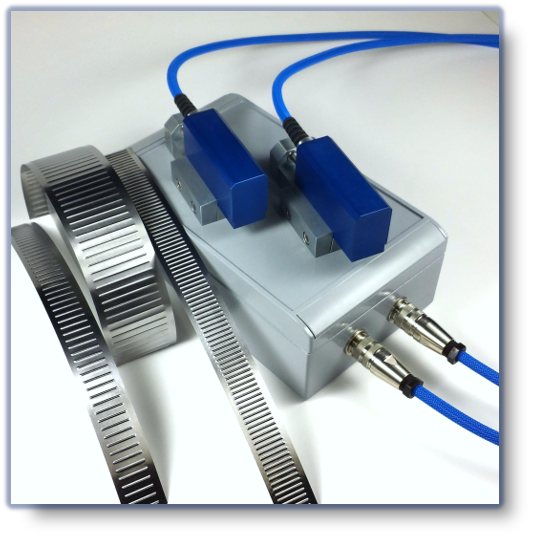

Customized Rack Mount Design

The Torque and Power Measurement System (TPMS) is customized to our client's application.

This Rack Mount Design has analog outputs: RPM, Torque, and TTL.

Applications

- Real-Time Mechanical Power Monitoring

- Torque Monitoring

- Torsional Vibration Monitoring

- Transient Load Monitoring

- Torsional Natural Frequencies Measurement

- Rotor Health/Condition Monitoring

- Shaft Coupling Load Monitoring

- Gearbox Efficiency, Gear Vibration

Industries

- Electric Power Generation (Nuclear, Fossil, Hydro…)

- Marine/Shipping (Drive Shaft Monitoring)

- Mining

- Oil and Gas

- Automotive

- Aviation/Aerospace

- Research and Development

Custom Encoder Belt

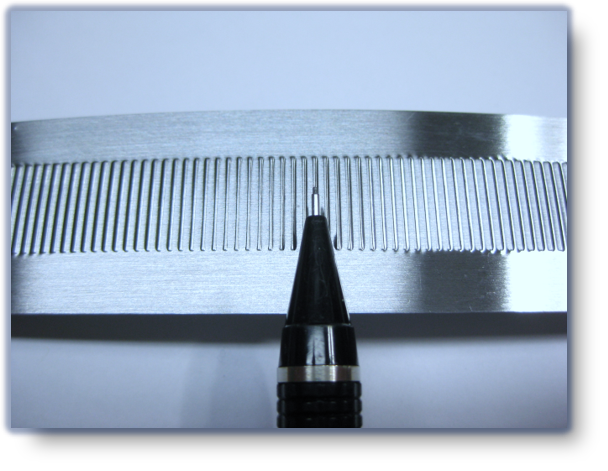

- Custom Encoder Design for the Highest Accuracy

- Any Shaft Diameter

- Custom Pitch and Width

- Lightweight Design: 12 gram/m

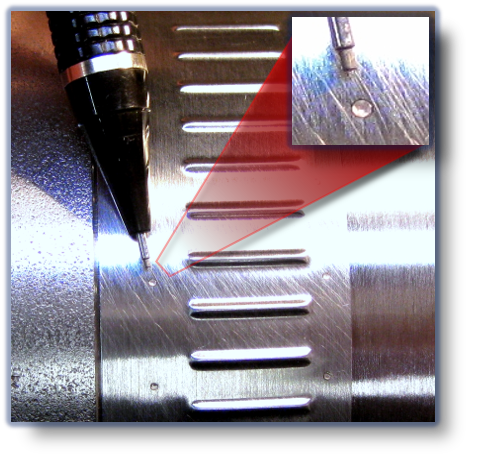

- Installation with Micro Spot Welding

- Installation using Epoxy Adhesives

- For Testing and for Permanent Installation

- Rapid Installation

- Wide Encoder Belts for Excessive Thermal Expansion

- Reliable Magnetic Operating Principle

- Pitch Variation < +/-0.002 inch (+/-0.051mm)

- Easy Removal

TPMS High-Resolution Encoder Belt

The High-Resolution Encoder Belt can have 0.04in (1mm) pitch to provide high-resolution Torque and Power measurement. It was designed to test low RPM and small diameter shafts.

TPMS Introduction Video

A short, 2 minutes YouTube video describes the advantages of the TPMS over existing technologies.

TPMS Lab Demonstration Video

This YouTube video demonstrates the TPMS signal response for an alternating 0.005 degree angular displacement.

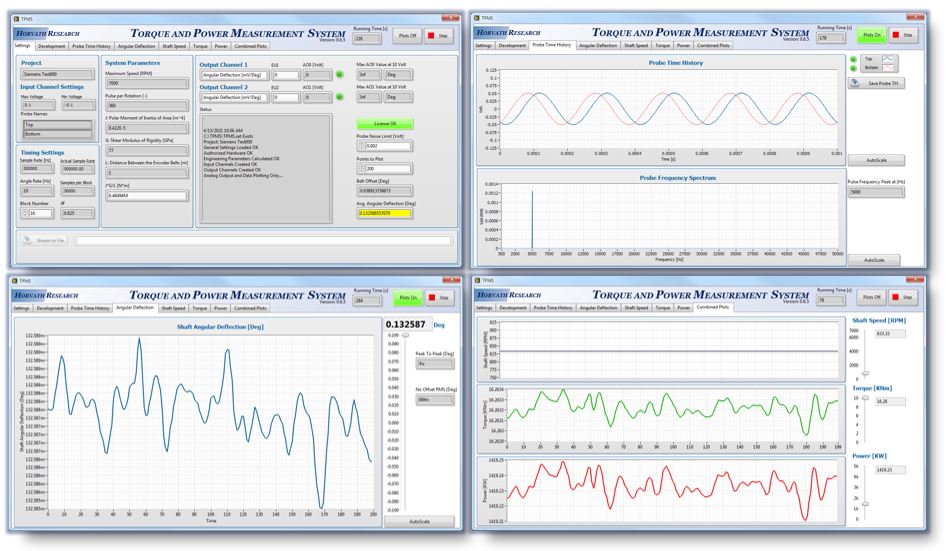

Customized Graphical User Interface

- Time Histories

- Frequency Spectra

- Angular Deflection, Twist [Deg]

- Shaft Speed [RPM]

- Torque [kNm]

- Power [kW]

- Settings