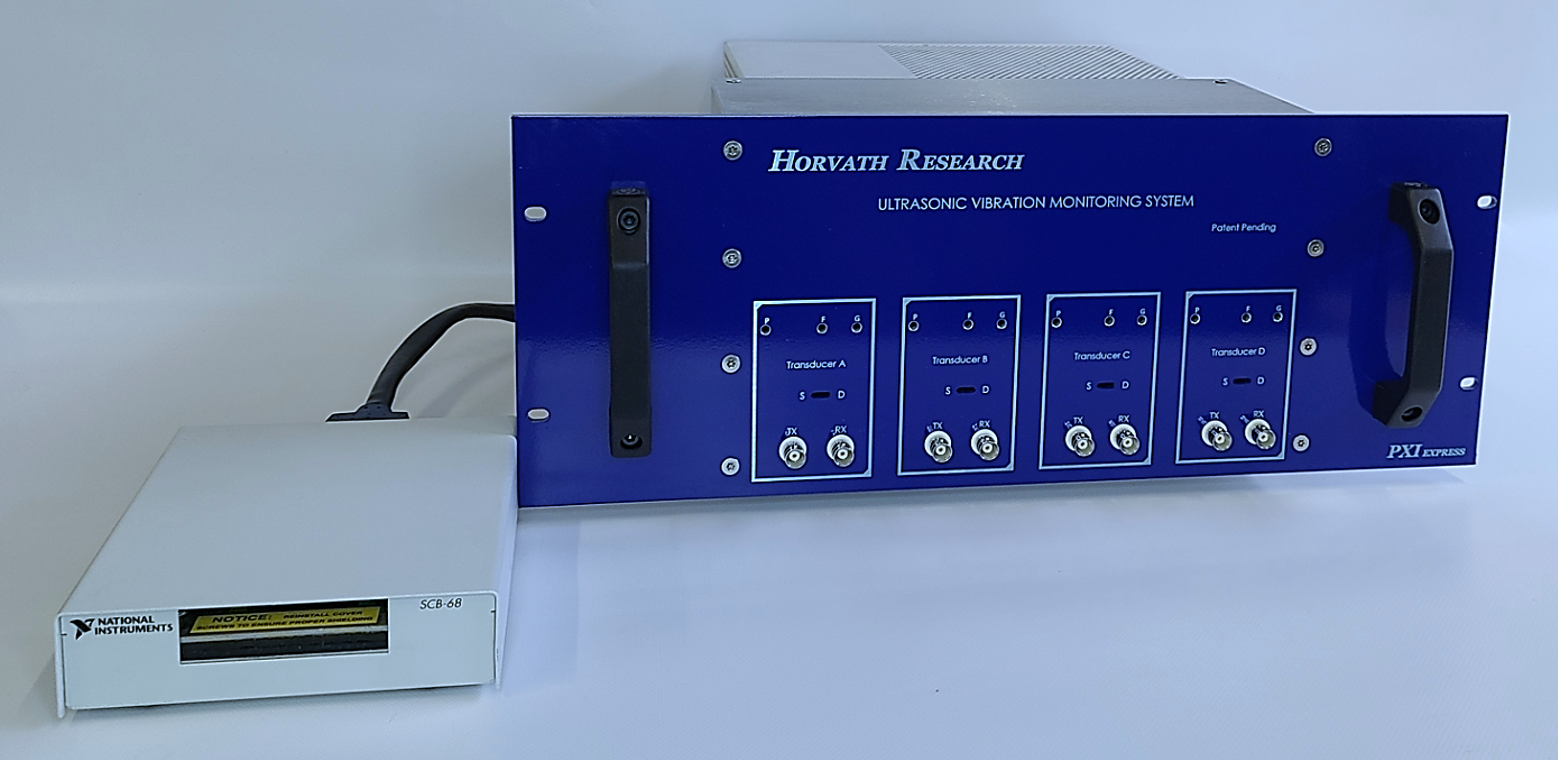

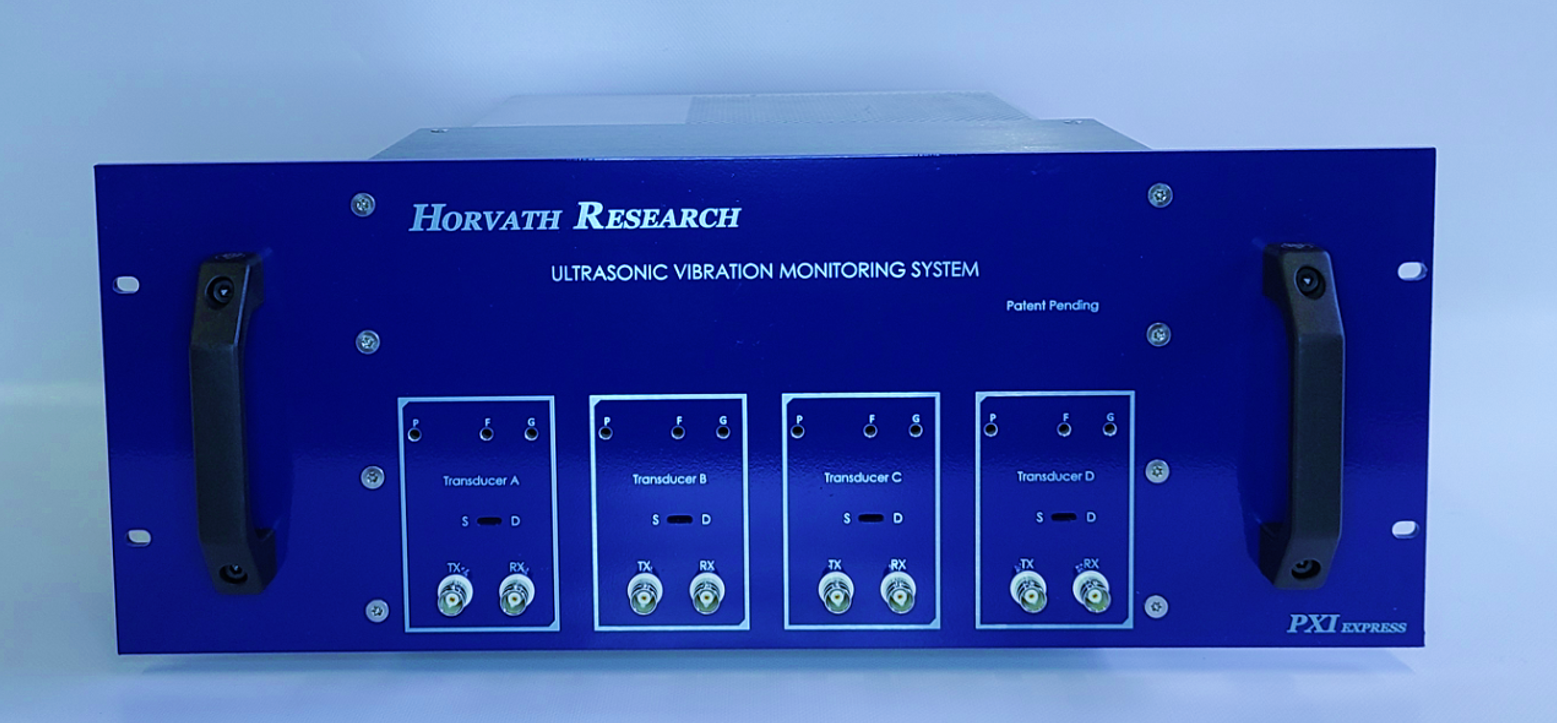

Ultrasonic Vibration Monitoring System

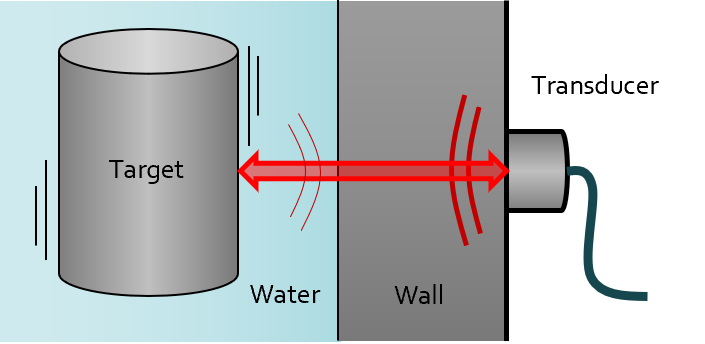

The Ultrasonic Vibration Monitoring System (UVMS) was developed to address the industry’s need to monitor the vibration of components through a pressure boundary.

Operating Principle

- Time of flight measurement of an ultrasonic pulse.

Test Data

- Jet Pump Target through 6-inch BWR Cladded Wall.

- The movement of the reflected echo.

Features

- Vibration/Clearance Monitoring

- No Modification to the Pressure Boundary

- Analog Voltage Outputs (4 Channel)

- Digital Outputs: In Range/Warning/Alarms

- Logging Other Plant Signals/Data

Applications

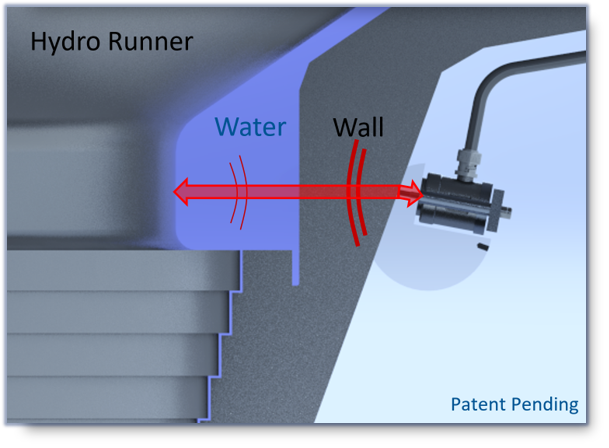

- Hydro Runner Clearance and Seal Gap Monitoring

- Valve Internal Vibration Monitoring

- Pump Impeller Clearance and Vibration Monitoring

- BWR Jet Pump

- PWR Control Rod Drive Mechanism and Core Barrel

- Heat Exchangers

- Startup Testing, Commissioning

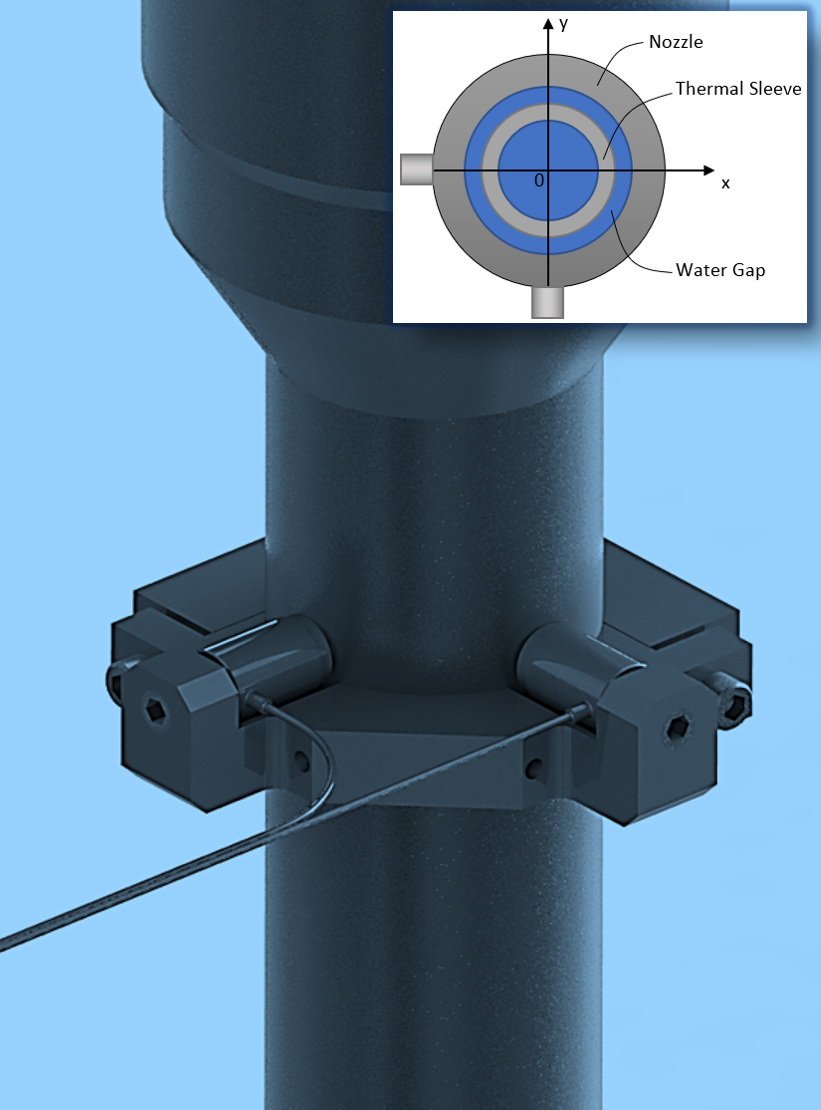

Control Rod Drive Mechanism

- CRDM Thermal Sleeve Vibration Monitoring.